Gauge

- Home

- Our Services

- Gauge

Introduction to Gauge Solutions

A machine vision gauging system measures distances between two or more points on an object to verify that they meet specifications. If the measurements do not meet the criteria, the system sends a fail signal to the machine controller, activating a reject mechanism that ejects the object from the line.

Measurement tools help establish reliable feature-based thresholds. These tools output quantitative information, either in pixels or real-world units, for the following parameters:

- Distance

- Angle

- Circle radius

- Calibration

Product fails to meet standards due to dimensional inaccuracies

Costly & time-consuming corrections required after product completion

Reduced customer satisfaction when receiving substandard products

Difficult to ensure consistency

3D Gap & Flush Inspection

Item Verification

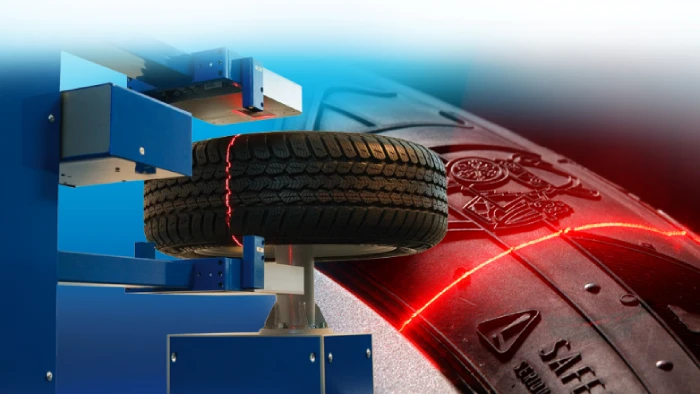

3D Tire Inspection

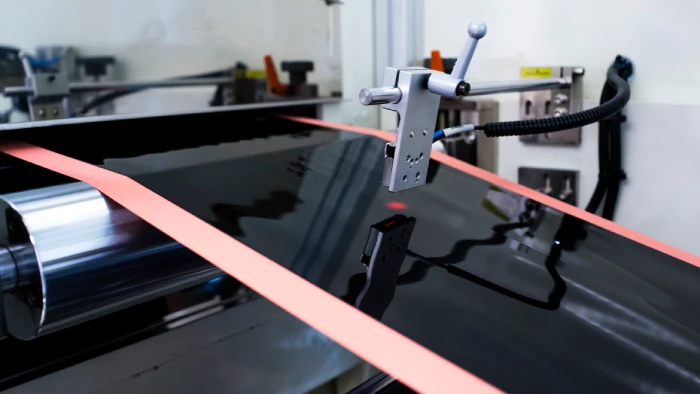

EV Battery Electrode Solutions

High accuracy & error reduction

Increased productivity

Lower production costs

Enhanced product quality

Greater flexibility

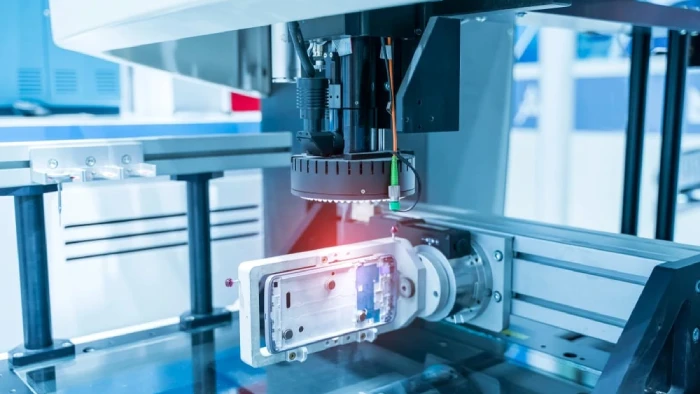

Quality starts with precision in every product

Transform your production line with unparalleled precision. Our Gauge Solution ensures every product not only meets but exceeds specifications, eliminating defects and delivering perfect measurement. From pinpoint precision to real-time feedback, our solution catches flaws before they cost you.