Guide

- Home

- Our Services

- Guide

Introduction to Robot Guidance Solutions

Machine vision guidance helps locate and orient parts, ensuring they meet specified tolerances and are correctly positioned for assembly. It enables robots and machines to identify and align parts accurately in 2D or 3D space, automating tasks like palletizing, assembly, and positioning on conveyors.

Applications & Cases

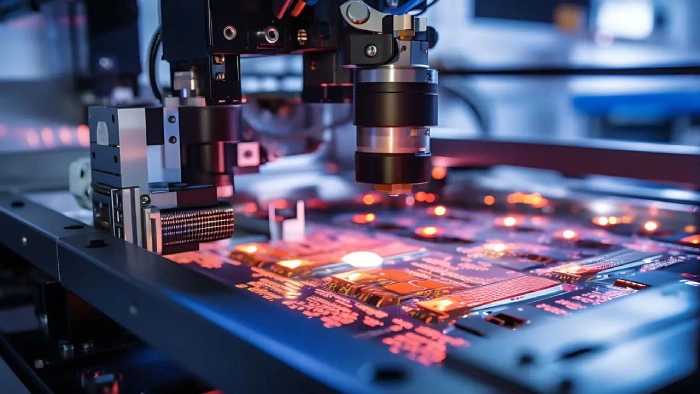

Automatic Electronic Assembly

High-precision automated systems efficiently assemble delicate electronic components, ensuring reliability, accuracy, and speed in production.

Automotive Welding

Advanced welding solutions deliver consistent, high-quality joints for automotive parts, optimizing strength, safety, and manufacturing efficiency.

Machinery Coating

Automated painting and coating systems provide uniform coverage, improve durability, and ensure a flawless finish for machinery components.

Medical Assembly

Robotic assembly systems in medical manufacturing meet strict hygiene standards, minimizing contamination and maintaining superior product quality.

Previous

Next

Benefits of Vision Guidance Technology

High accuracy

Ability to handle diverse products

Automatic calibration

Flexible integration

Perfect your workflow with guided accuracy

Our advanced technology allows robots to see in 2D and 3D, understand their environment, and execute complex tasks flawlessly. From exact part positioning to seamless palletizing and assembly, your production line becomes smarter, faster, and infinitely more efficient.

Step into the future where robots think, adapt, and perform with unmatched accuracy. Transform your workflow, elevate your standards, and let innovation take the lead.