Inspection

- Home

- Our Services

- Inspection

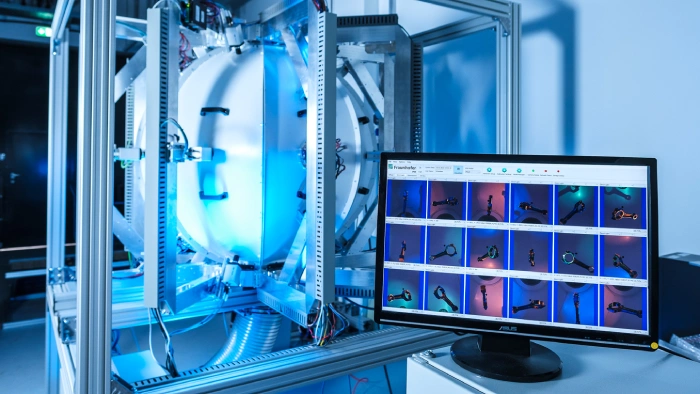

Introduction to Vision Inspection

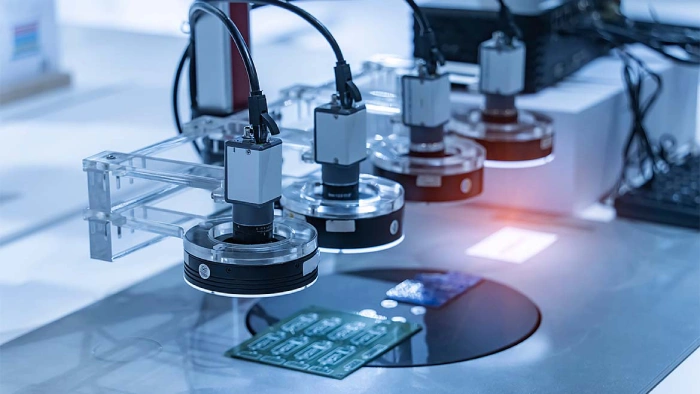

Our machine vision inspection system is designed to detect defects, contaminants, functional flaws, and other irregularities in manufactured products with high precision and efficiency.

With real-time monitoring capabilities, our solution not only identifies issues during production but also provides actionable insights to improve manufacturing processes. Trust our system to maintain the highest quality standards and optimize your production line.

360° Inspection

Cap & Label Inspection

Part Presence/Absence

Fill Level Inspection

Improved product quality & efficiency

Reduced costs & human errors

Enhanced quality control with high precision

Scalability for future growth

Inspect every flaw, perfect every product!

Quality is never an accident—it’s a result of precision, technology, and constant vigilance. Our vision inspection systems detect defects, contaminants, and irregularities with unmatched accuracy. Real-time monitoring empowers your team to resolve issues instantly, minimizing waste and maximizing efficiency.