Identification

- Home

- Our Services

- Identification

Introduction to Identification Solutions

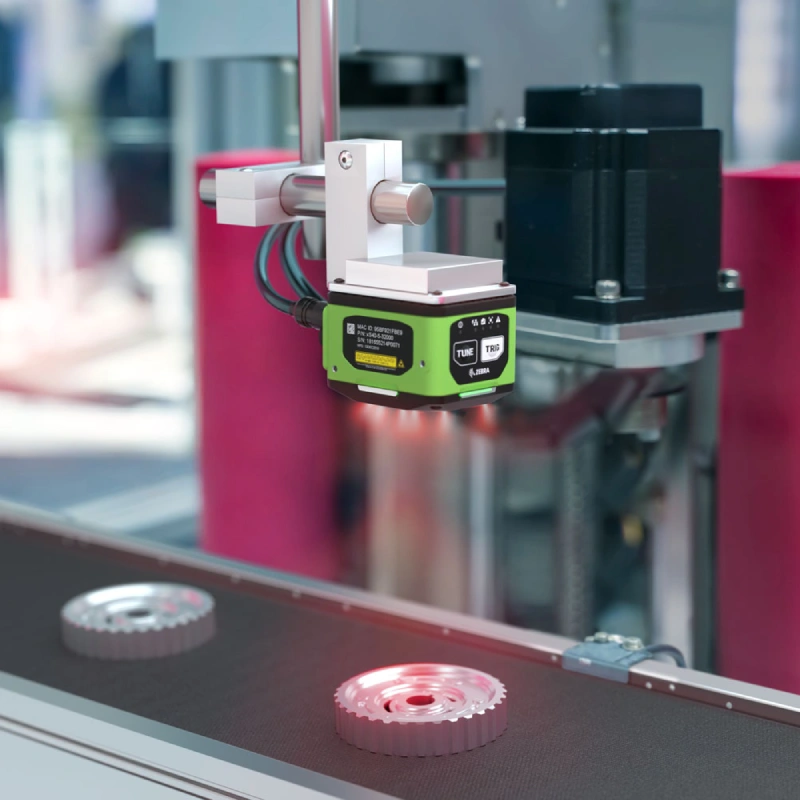

A machine vision system for part identification and recognition reads barcodes (1D), DataMatrix codes (2D), direct part marks (DPM), and characters printed on parts, labels, and packages. Additionally, machine vision systems can identify parts by locating a unique pattern or identifying items based on color, shape, or size.

Applications & Cases

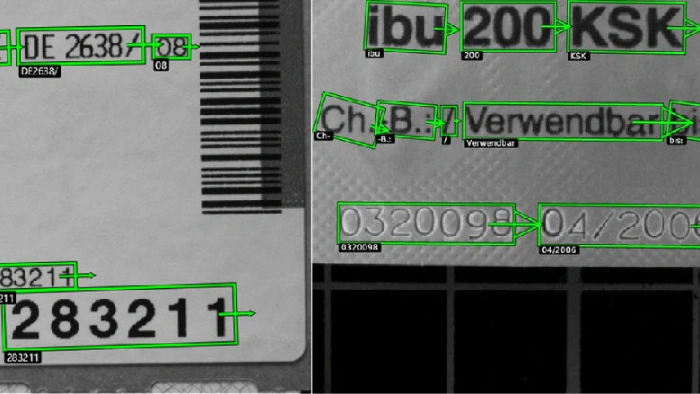

OCV/OCR

Train and recognize characters intuitively and quickly using AI technology. Accurately inspect the quality of printed characters to ensure compliance with production standards.

Barcode Inspection

Check for printing errors on barcodes precisely (defects, blur, decodability, edge contrast...), ensuring barcodes meet international standards such as GS1, HIBC, USPS and ISO/IEC15416.

Barcode Reading & Verification

Identify the position of codes and verify barcodes quickly and efficiently. The system is extremely user-friendly, suitable for various production and inventory management applications.

Print Quality Inspection (Dot Print)

Solution for checking the quality of inkjet printing (dot print) for each character. Make sure each printed point is clear, sharp, and not blurred or out of focus during the production process.

Previous

Next

Benefits of Identification Technology

Improve accuracy & reduce human errors

Increase efficiency by speeding up processes

Better & automated quality control

Lower operational costs

Enhance security against counterfeit products

Improve customer experience & satisfaction

Shape, color, code: Identify everything effortlessly!

Take the guesswork out of your production line with advanced identification solutions. From scanning barcodes and DataMatrix codes to reading direct part marks and recognizing patterns, colors, shapes, and sizes, our cutting-edge systems deliver accuracy where it matters most.